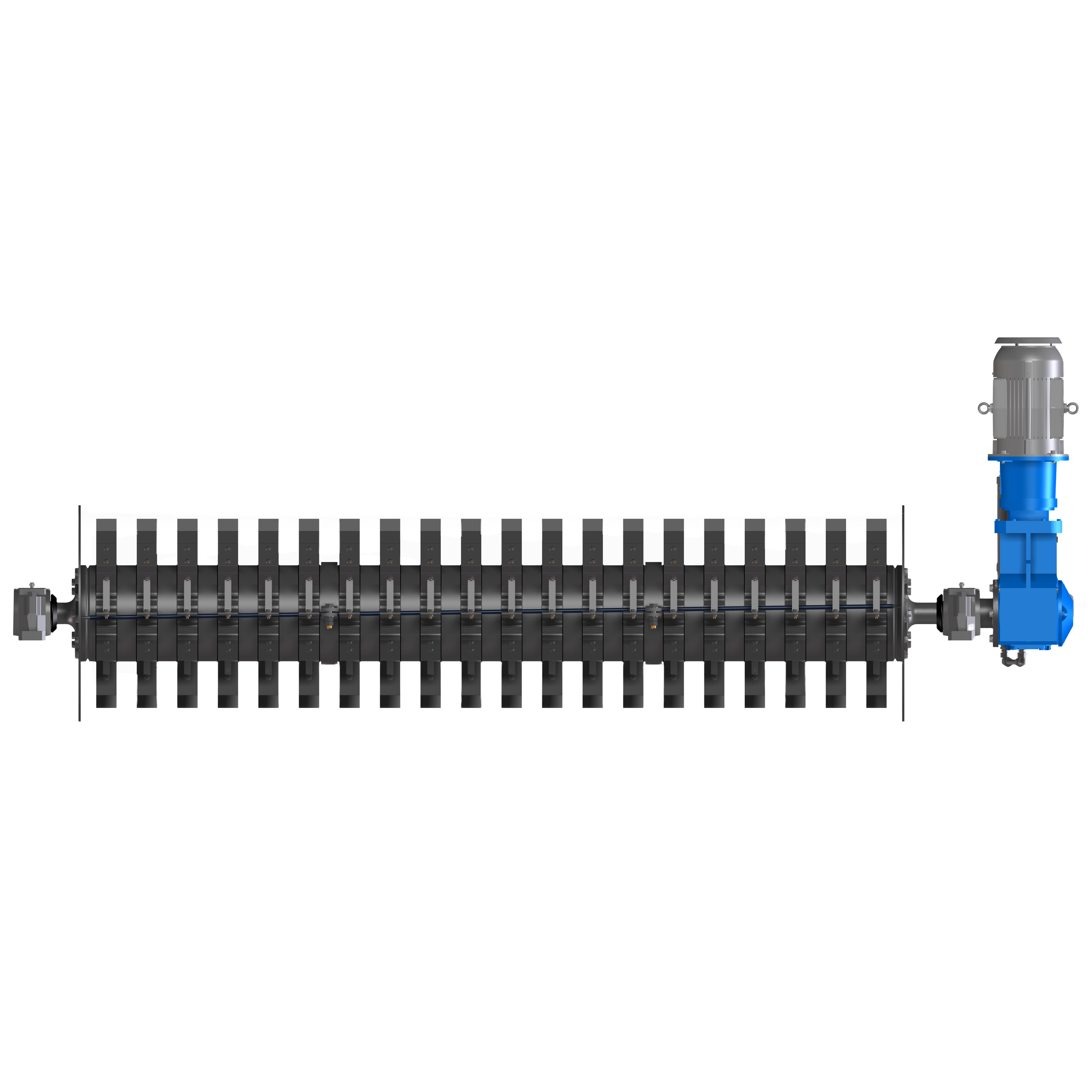

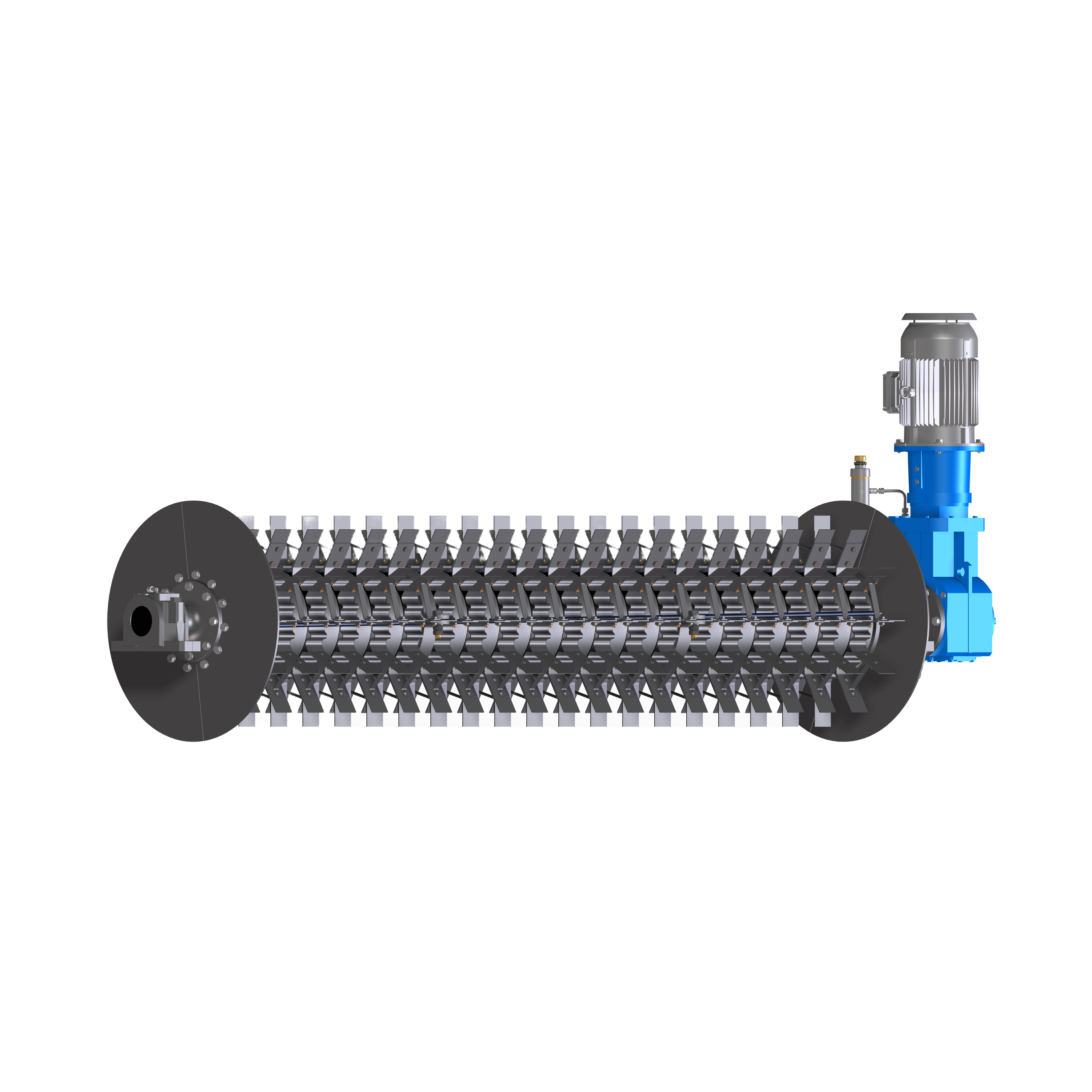

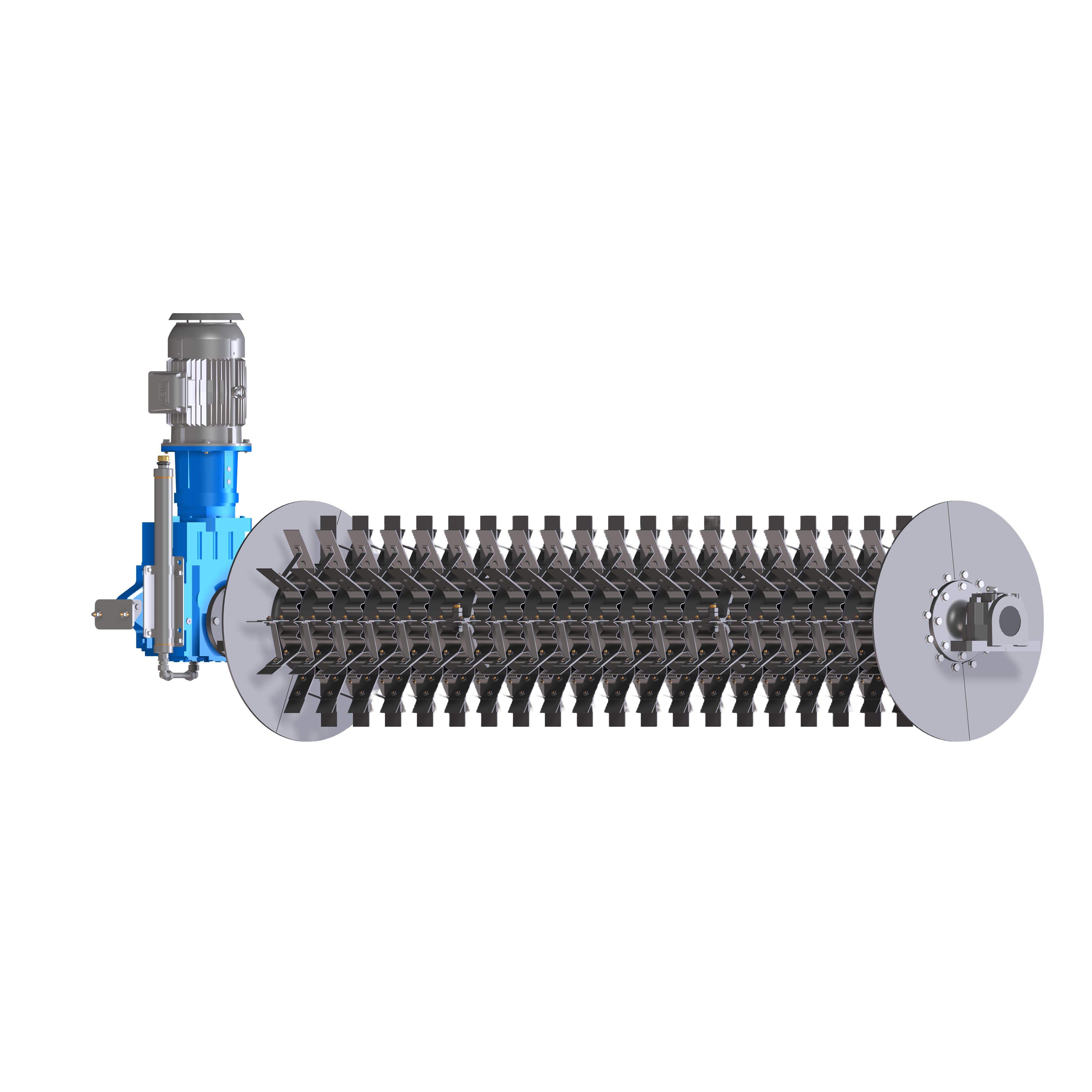

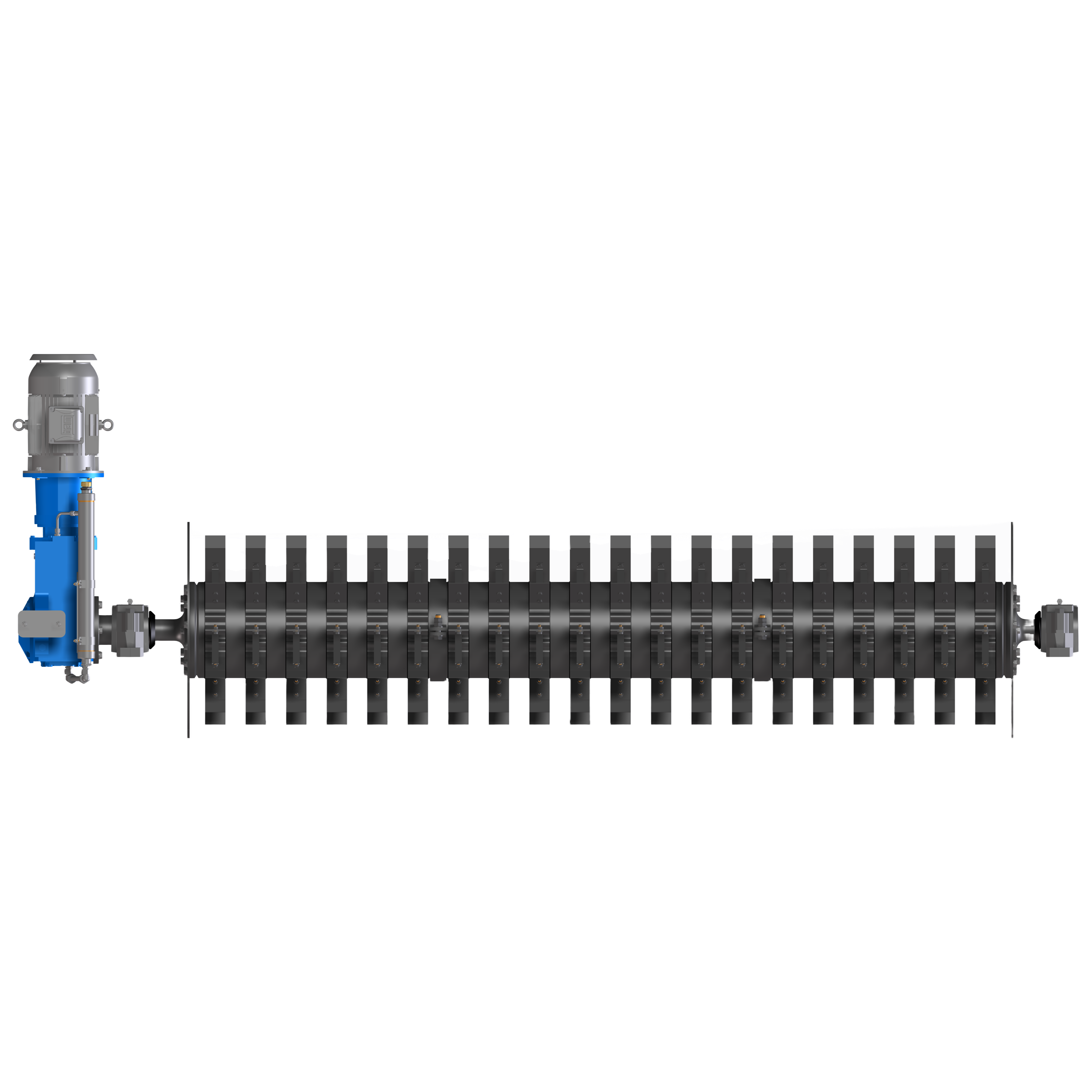

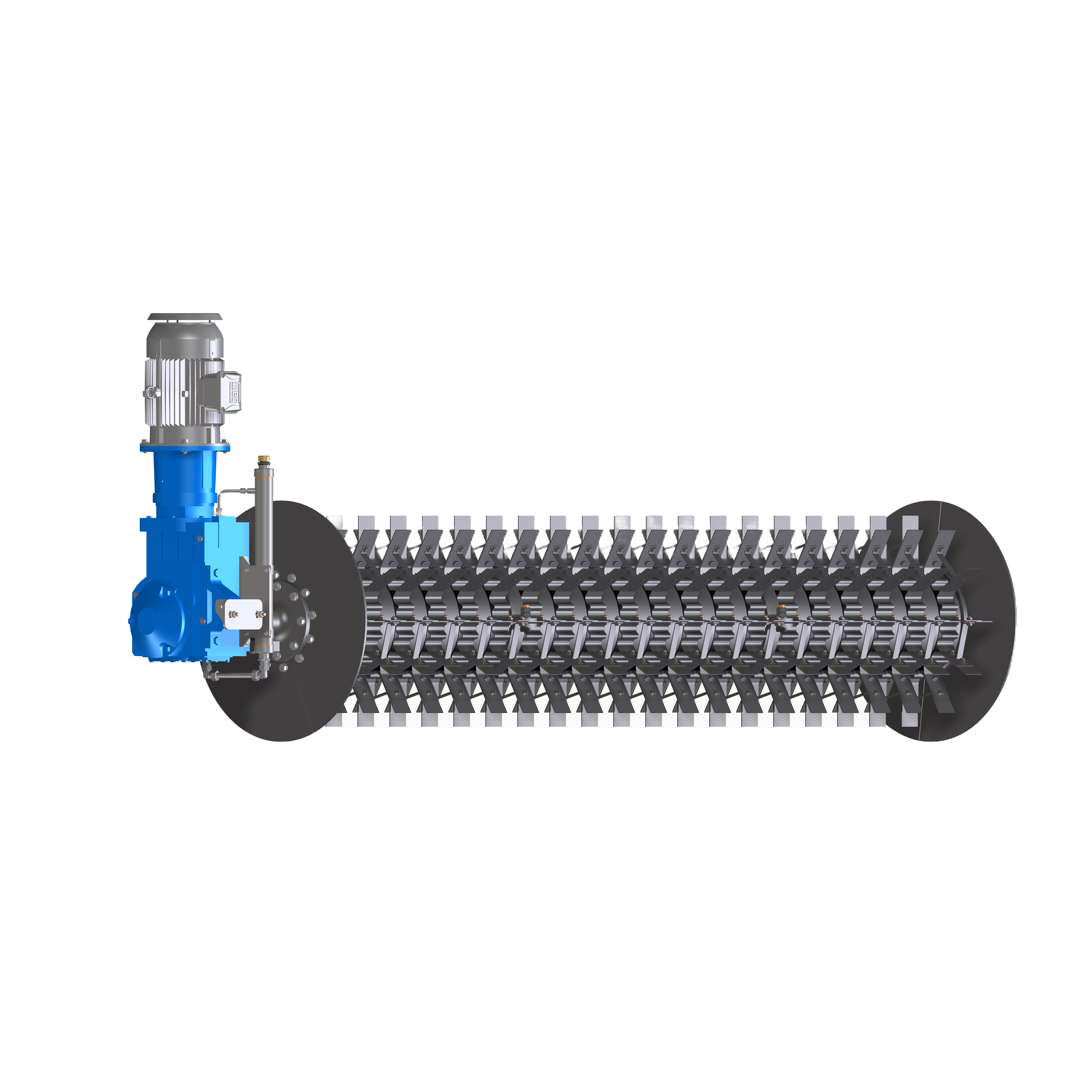

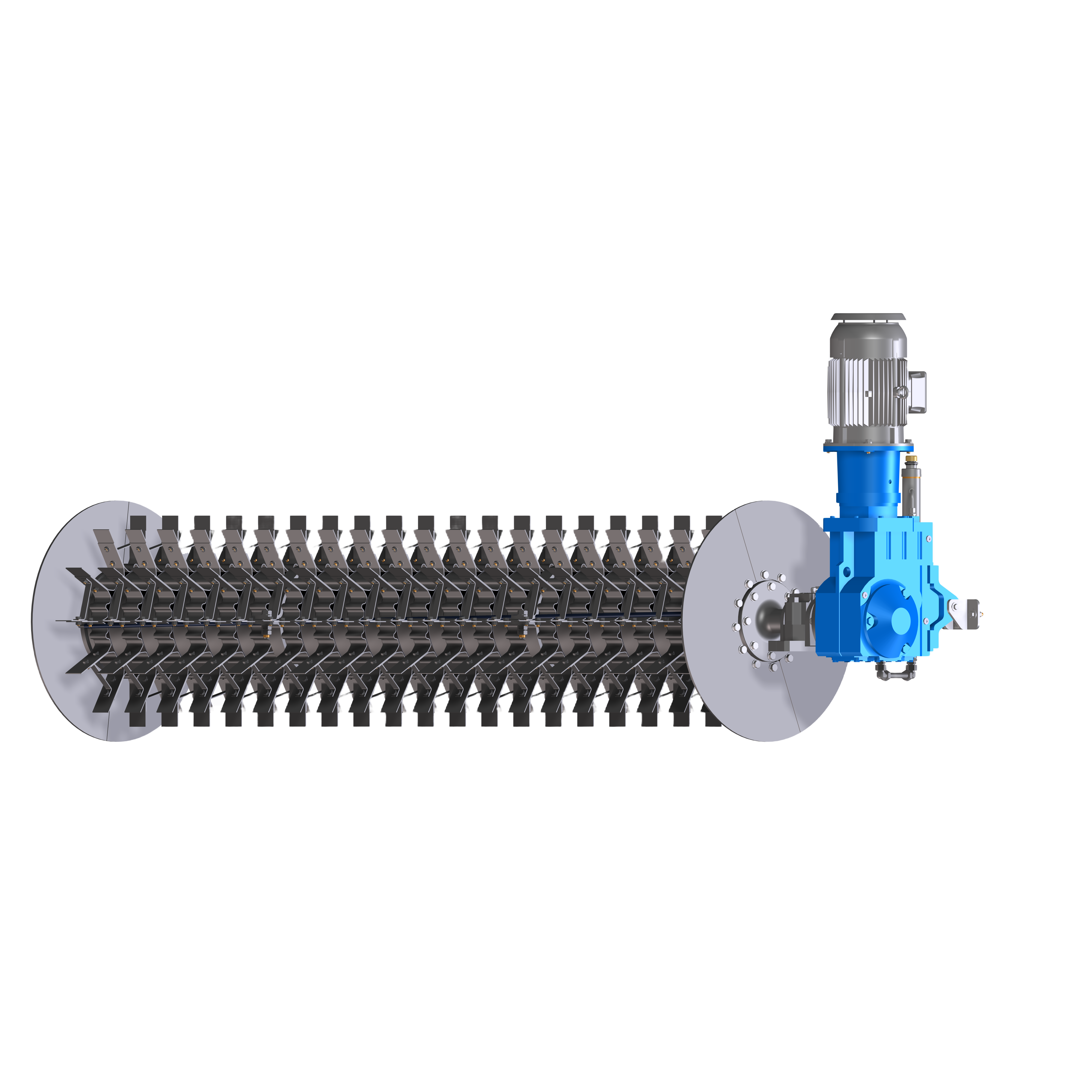

Landustrie borstelbeluchter

Wastewater aeration is the process of adding oxygen (O2) to wastewater to support aerobic pollutant degradation

The LANDY brush aerator’s rotor introduces oxygen into the water by creating intensive turbulence at the phase boundary between the wastewater surface and the air. The rotor also induces a strong directional flow pattern to ensure thorough mixing of the activated sludge, wastewater and oxygen.

Product specifications

detailed information

Brush aerators are horizontal shaft surface aerators used for oxygen transfer and directional mixing in wastewater treatment. The LANDY brush aerator’s rotor introduces oxygen into the water by creating intensive turbulence at the phase boundary between the wastewater surface and the air. The rotor also induces a strong directional flow pattern to ensure thorough mixing of the activated sludge, wastewater and oxygen. This flow pattern allows sedimentation-free operation in basin depths of up to 3.5 m. In deeper basins of up to 8 m, mixing should be supplemented by additional flow inducers with an intermittent mode of operation.

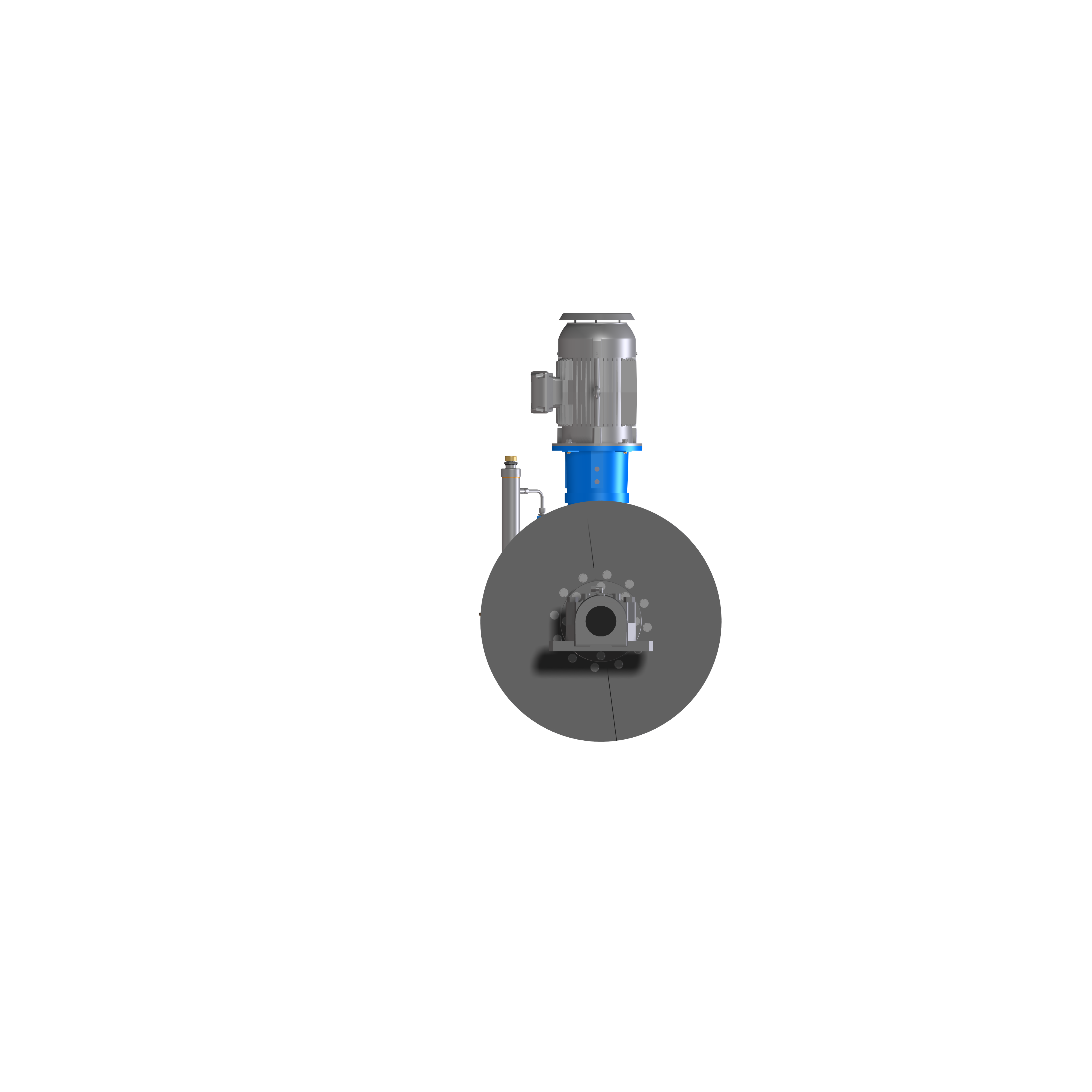

Splash plates are mounted on either end of the rotor shaft to minimise splashing onto the bearings and drive unit. Guide baffles downstream of the brush aerator are often specified to ensure uniform aeration and mixing down to the tank floor and to maximise efficiency.

The scope of LANDY brush aerator projects can be tailored to your requirements. For example, the scope can include an access bridge and inspection covers to facilitate offsite pre-fabrication, quick and safe installation, and ease of inspection and maintenance.