Hubert Microfilter

A Hubert micro screen or microstrainer can be found in freshwater intakes, acting as fine pre-filtration system of potable water for production plants, or production plants that consume a lot of process water. In addition, this filter can be applied for process water recirculation. The recovery of useful raw materials from process water, stricter discharge requirements, and recycling of process water makes the use of these engineered filters of increasingly interest. Other applications are treatment of effluent in a waste water treatment plant and pre-filtration in membrane filtration systems.

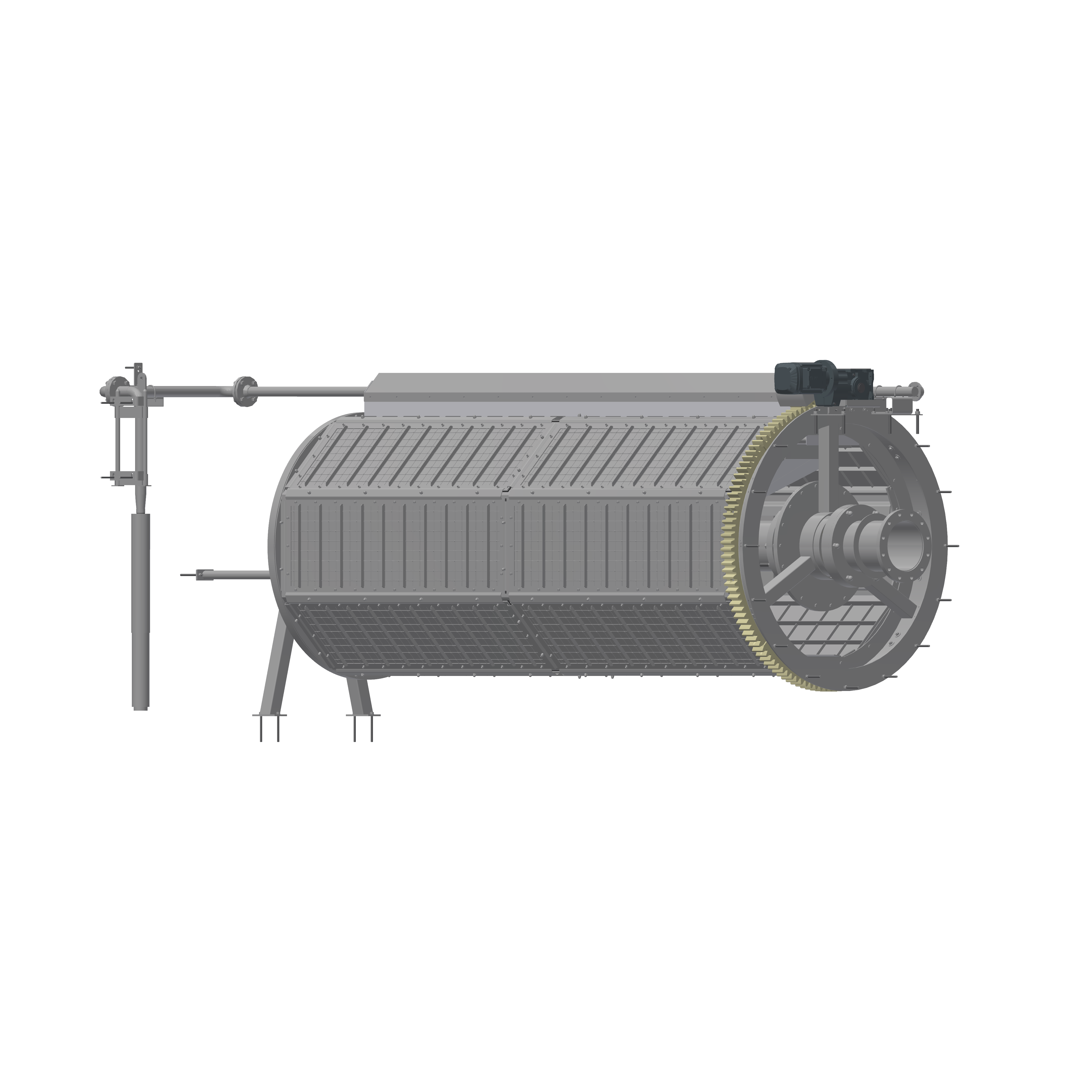

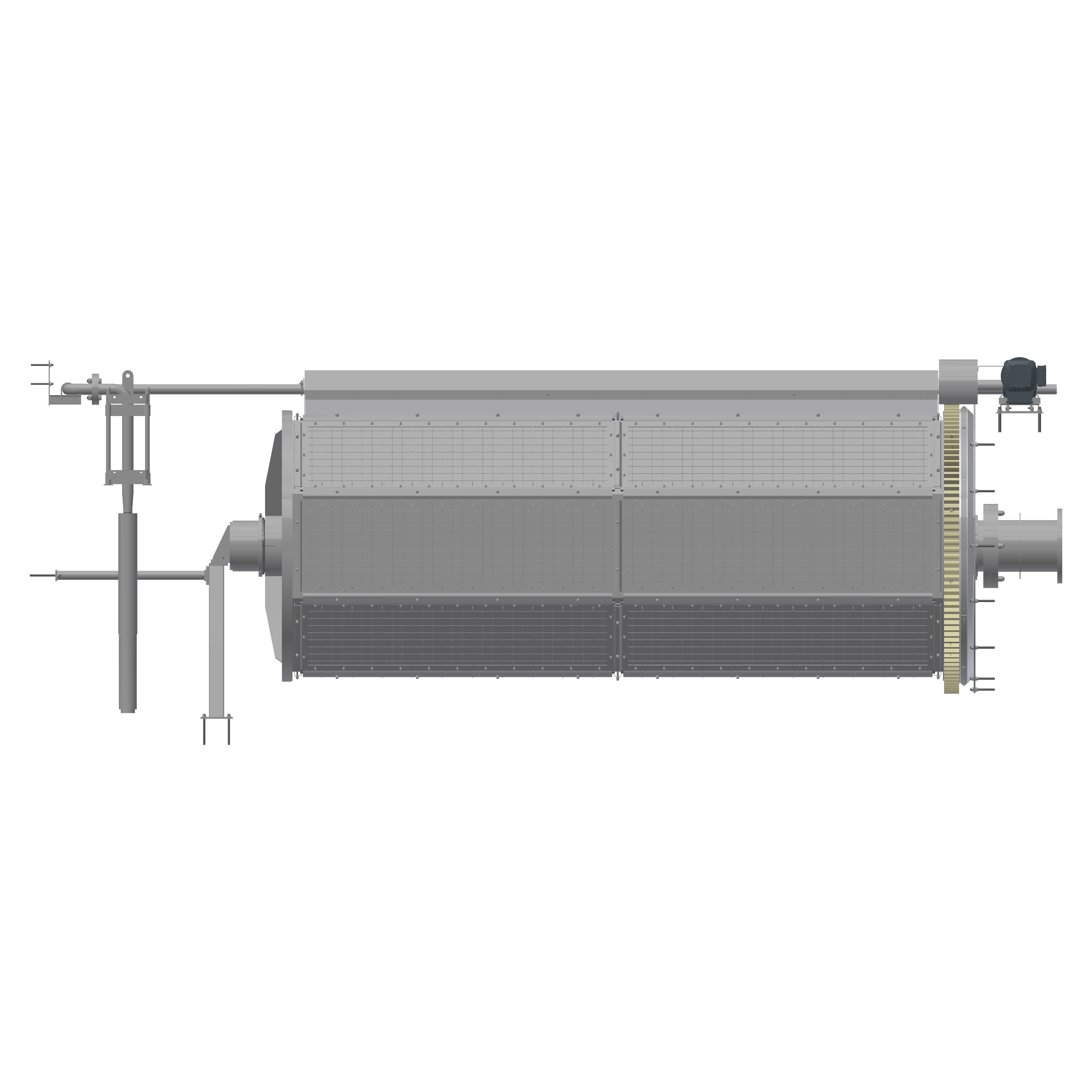

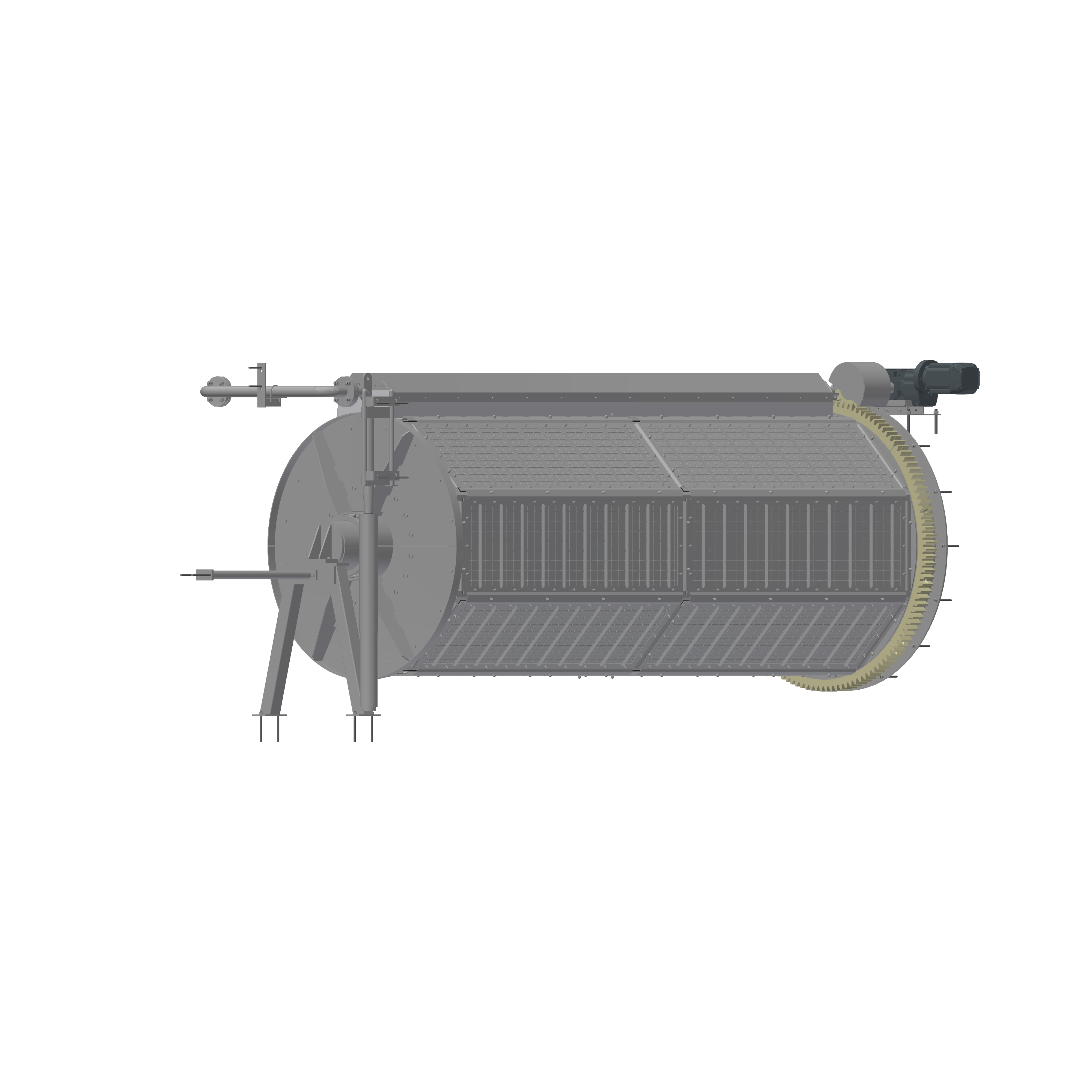

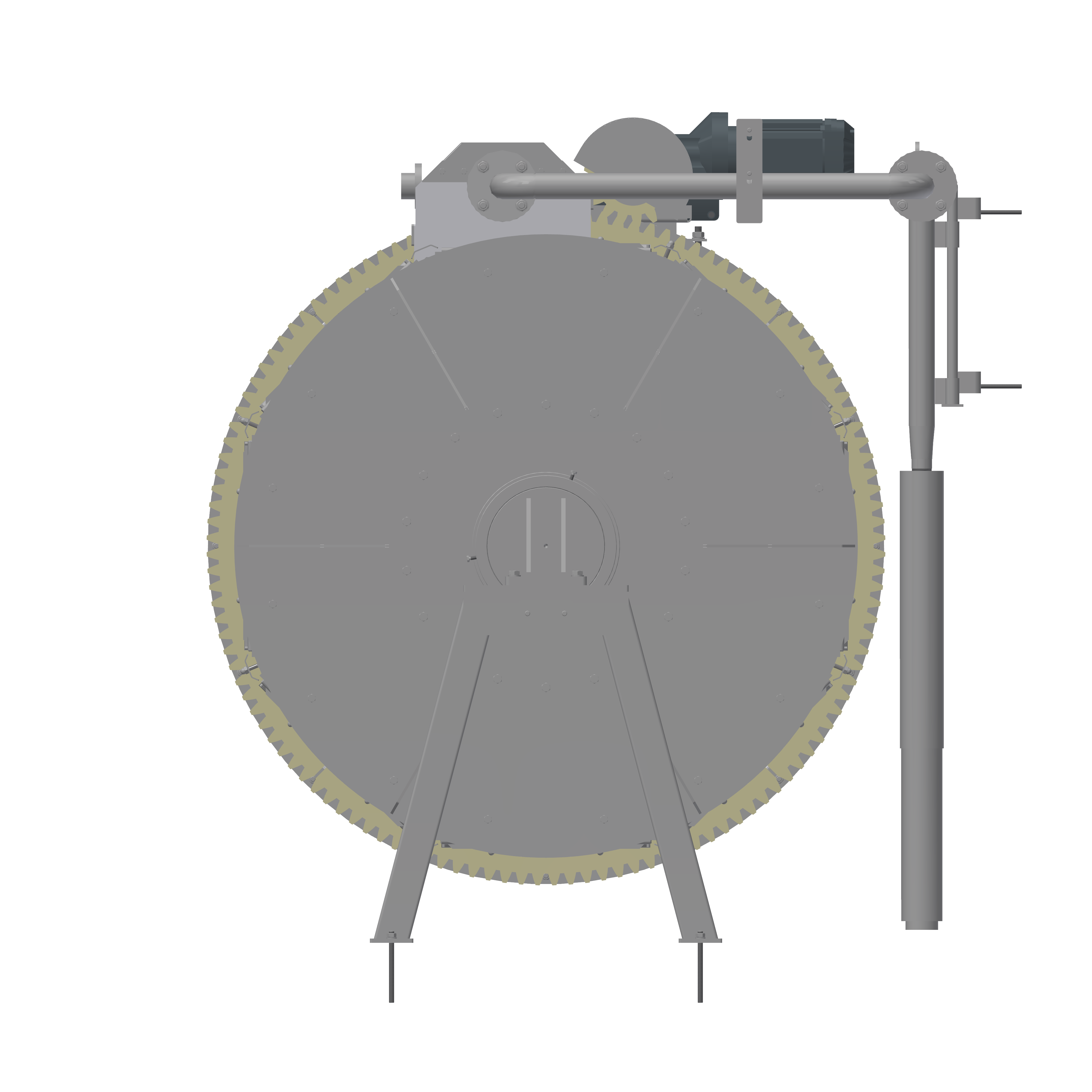

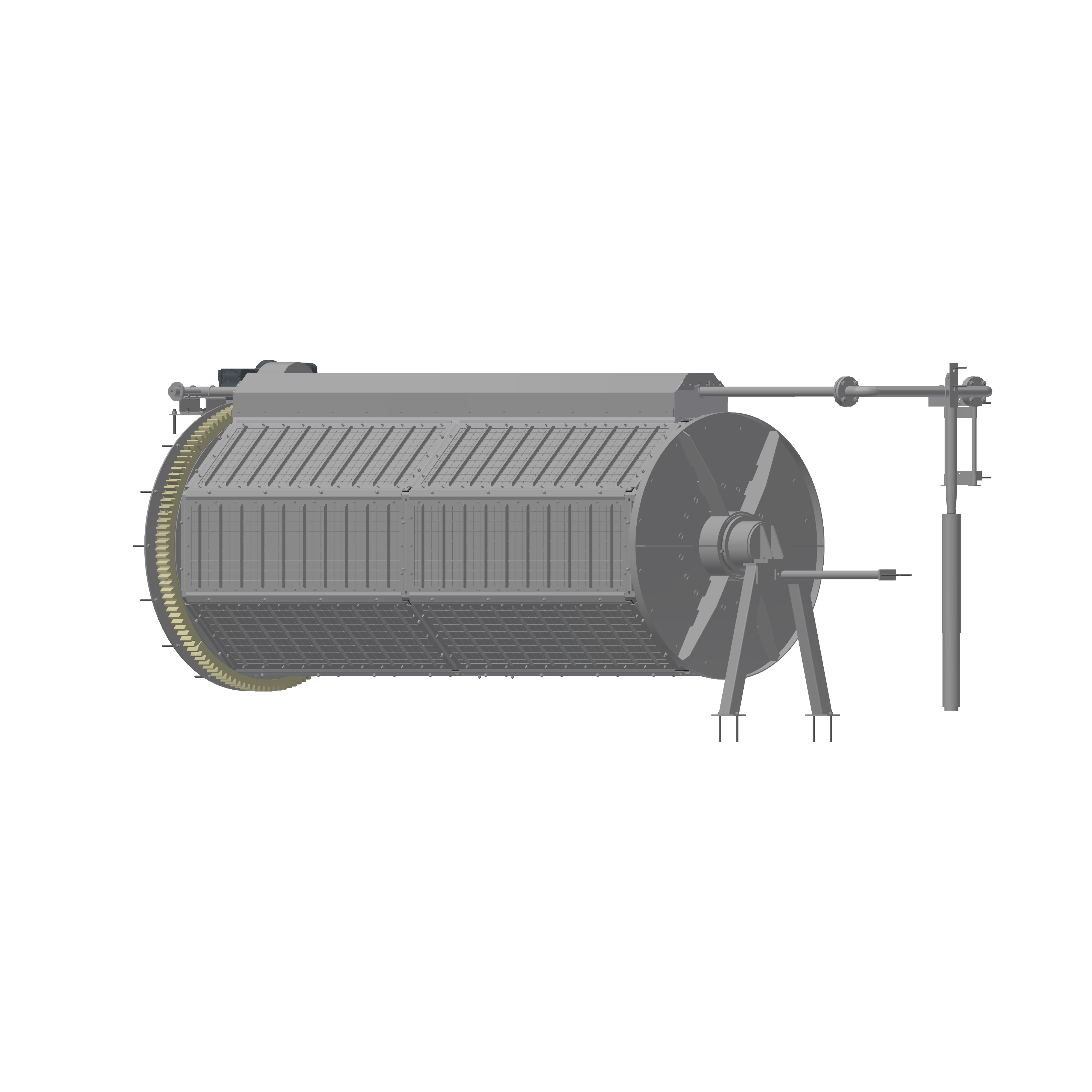

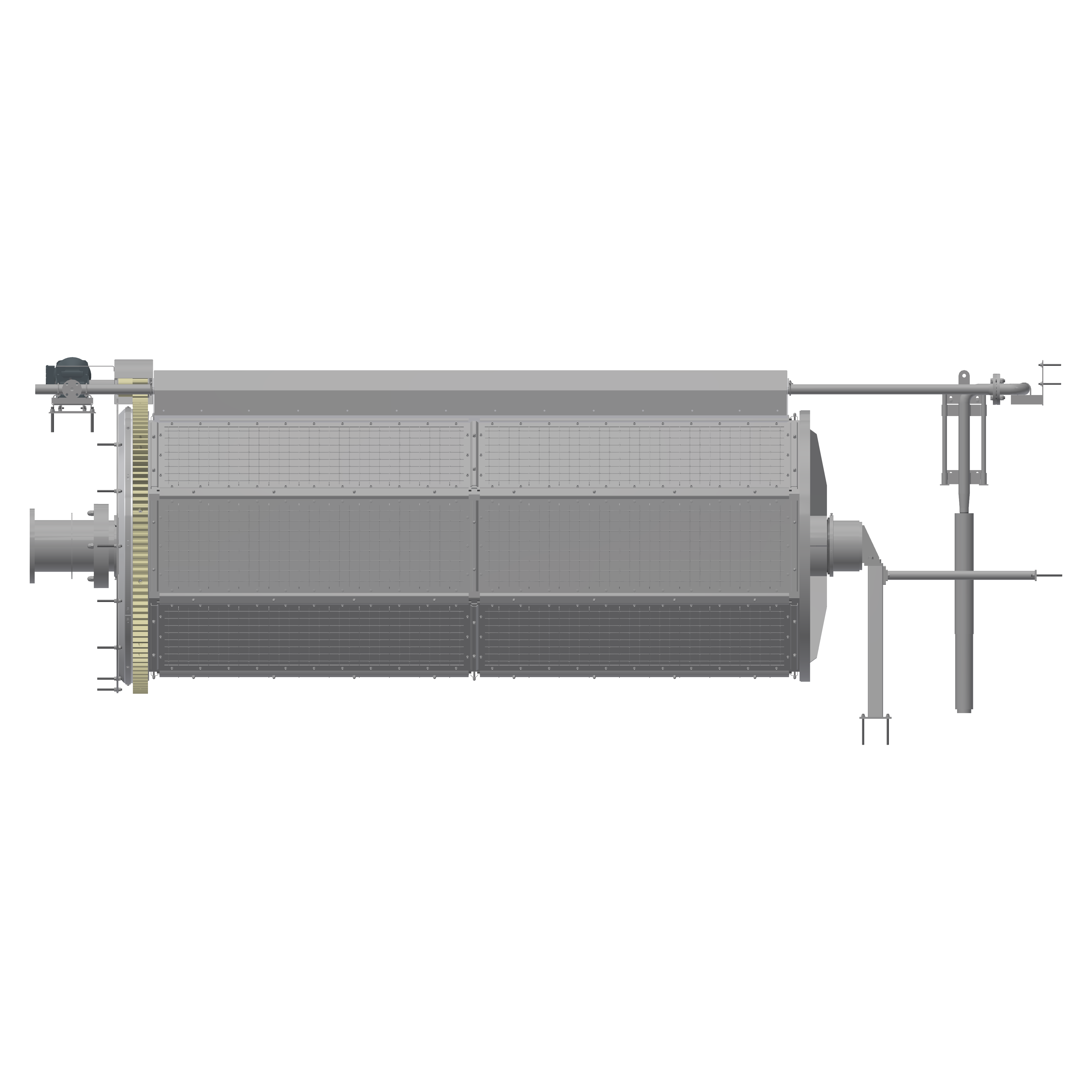

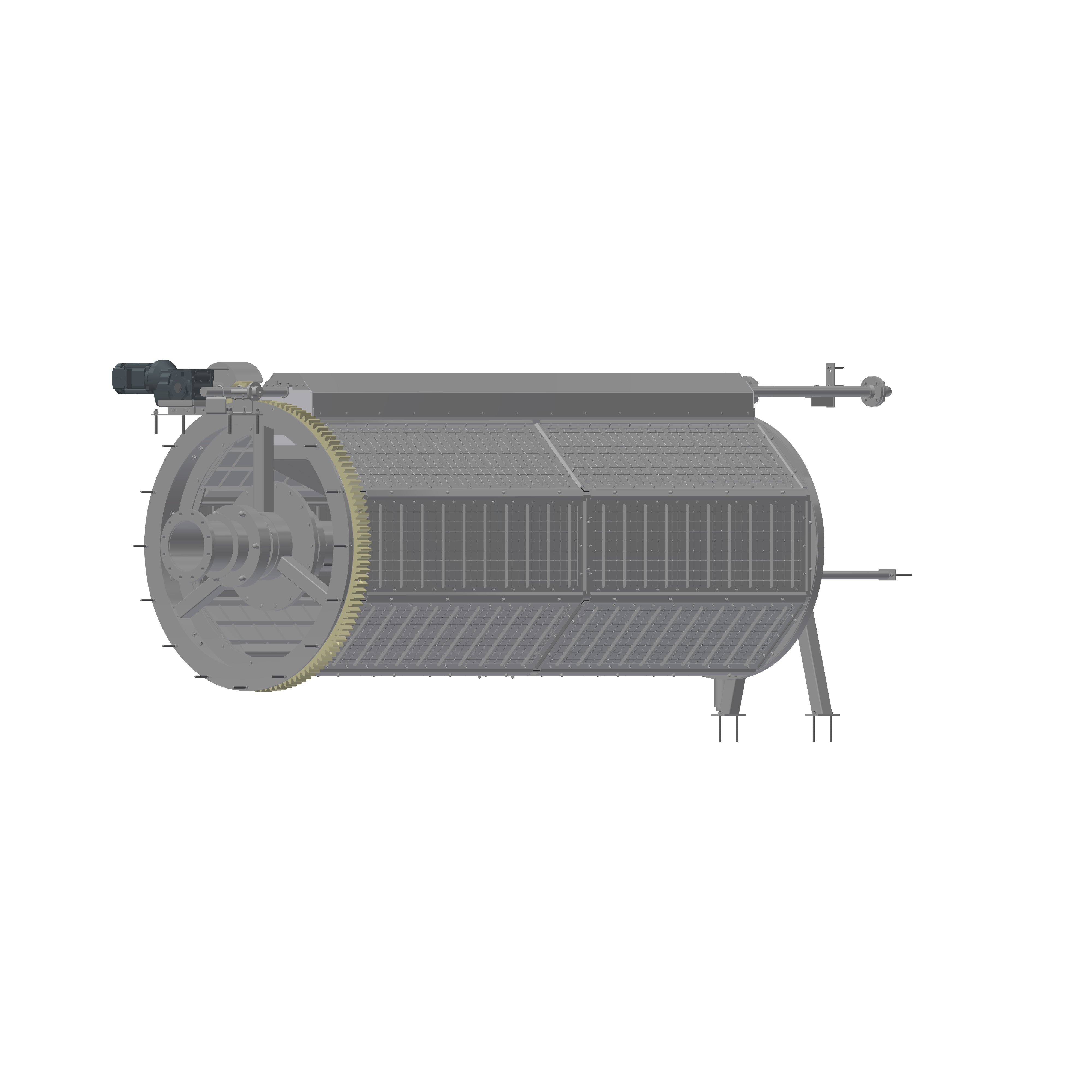

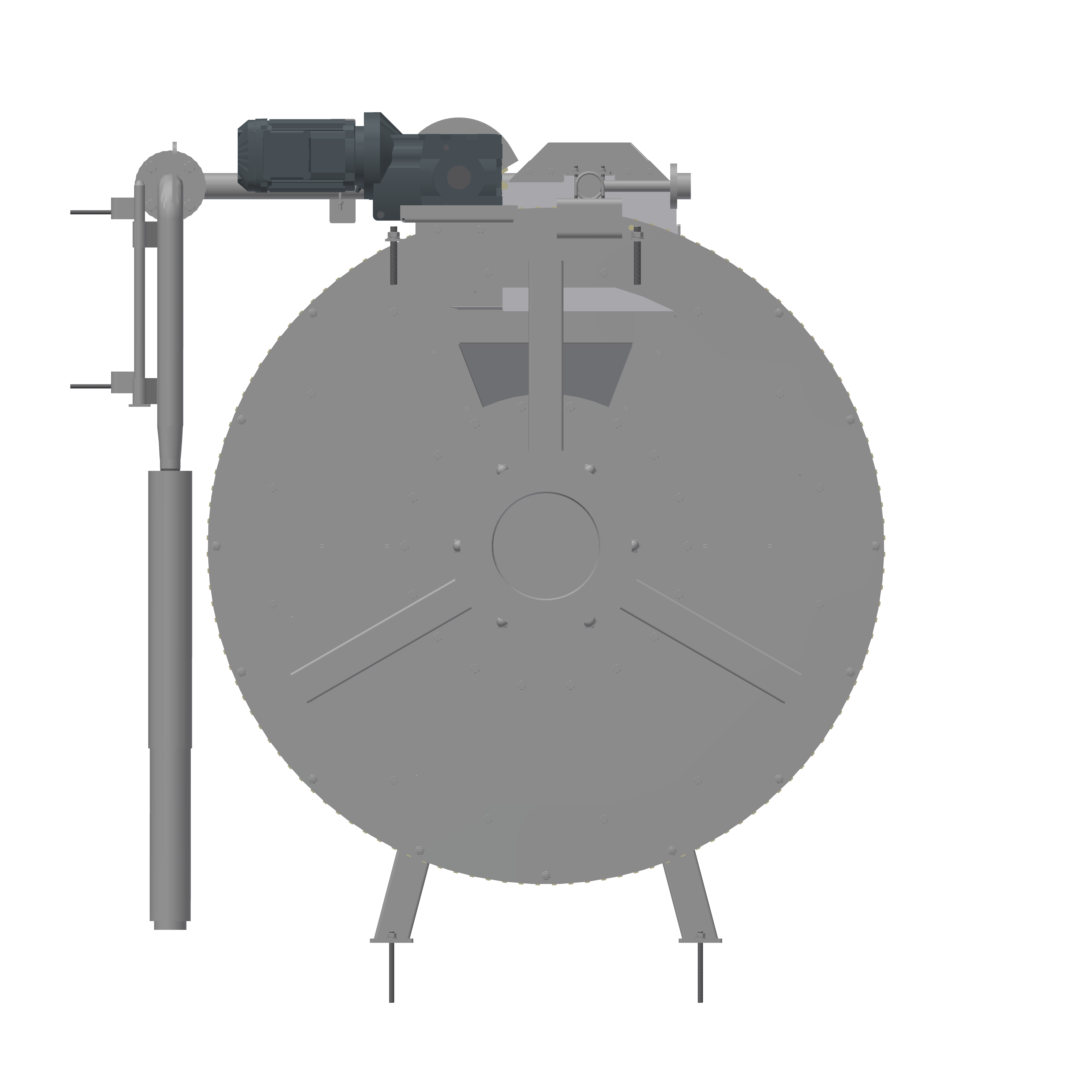

The Hubert microscreen system consist of a drum screen fitted along its outer circumference with filter screen panels. The drum is placed in a concrete pit or tank and rotates on a stationary hollow shaft fitted with one or more funnel-shaped debris collectors. The feedstock of water enters the drum axially and flows radially through the mesh panels. The dirt particles remain trapped in the mesh.

Product specifications

Detailed information

Flow rates can be up to 5000 m3/h per screen, depending on customer requirements and application. Woven fabric or mesh with a diameter of about 11 up to 500 micron is used as filter medium. This type of filter is usually used under free fall conditions. It is called micro screen because the filtration degree is less than 1 mm. The efficiency and capacity of a microstrainer depends on several factors including the characteristics of the fine filtration mesh (fabric), rotation speed of the microscreen, the quality of the water to be purified and the amount of backwashing water.

We also use perforated plate as filter medium, with a hole dia starting from 0.5~1 mm. In that case we call this type of filter a perforated (rotating) drum screen. Larger filtrations (> 1-2 mm) will be normally done by travelling band screens or larger vertical drum screens in open channels (water intake systems).