Hubert Damwanden

Hubert stoplog and sluice gate systems are always made-to-measure. Hubert stoplogs and sluice gates permit rapid and secure closure of very large inlet channels and pump chambers. Stoplogs and sluice gates are always designed according to project and customer specifications. A stoplog or sluice gate is typically installed in water intake systems upstream from coarse bar screens and drum screens or travelling band screens.

Using stoplogs or sluice gates makes periodic inspection and maintenance of screening systems and pumps possible by dewatering the separated part of the channel.

Product Specifications

detailed information

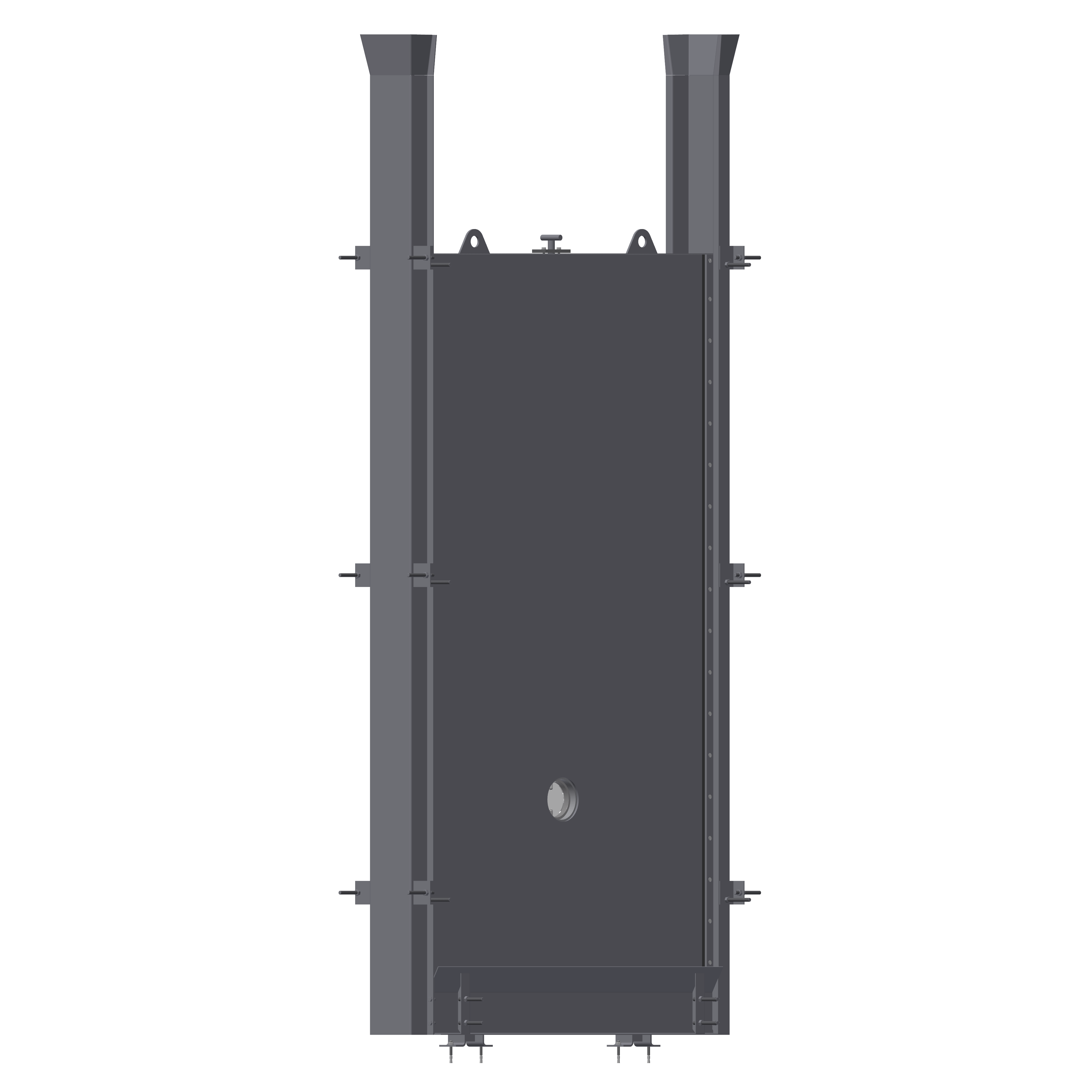

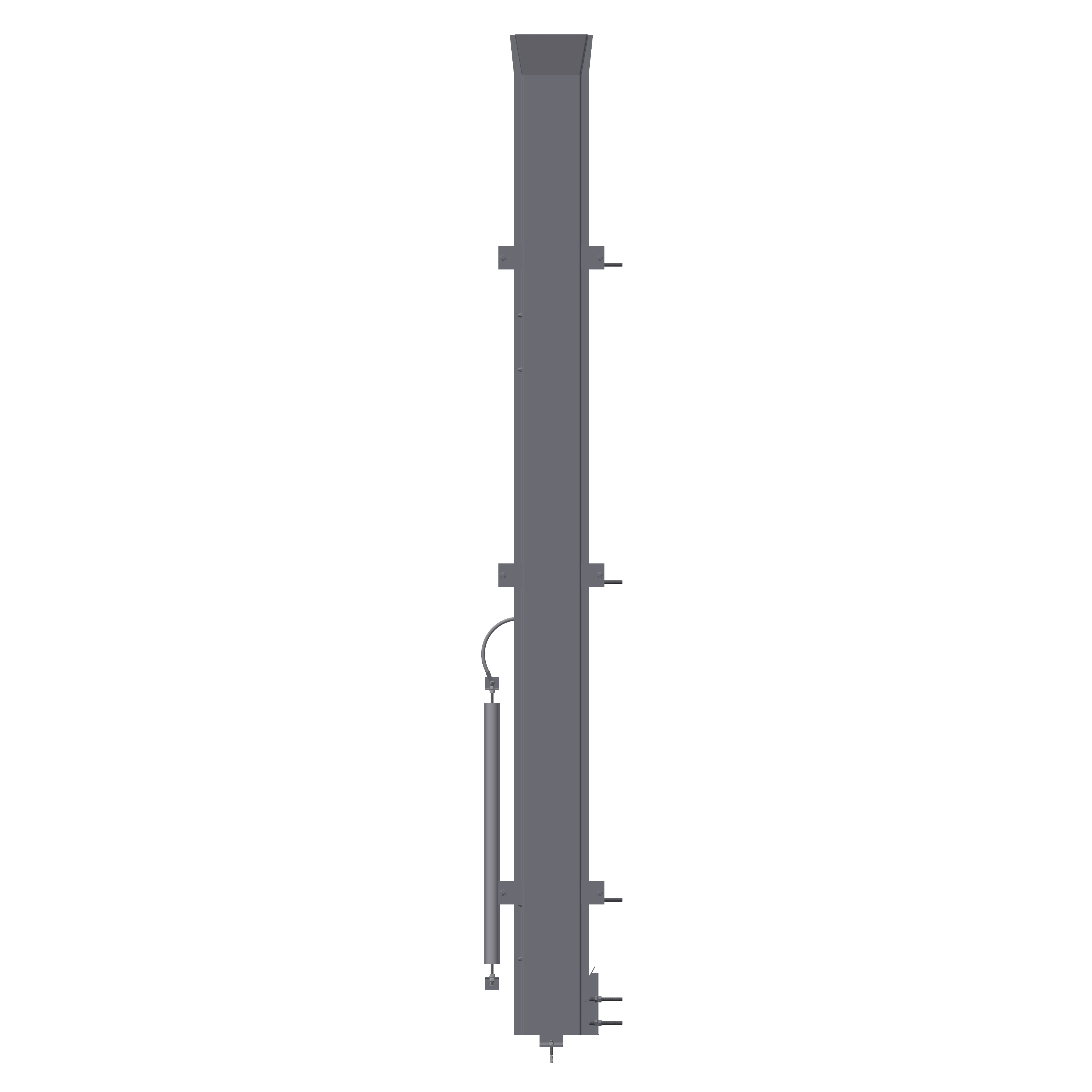

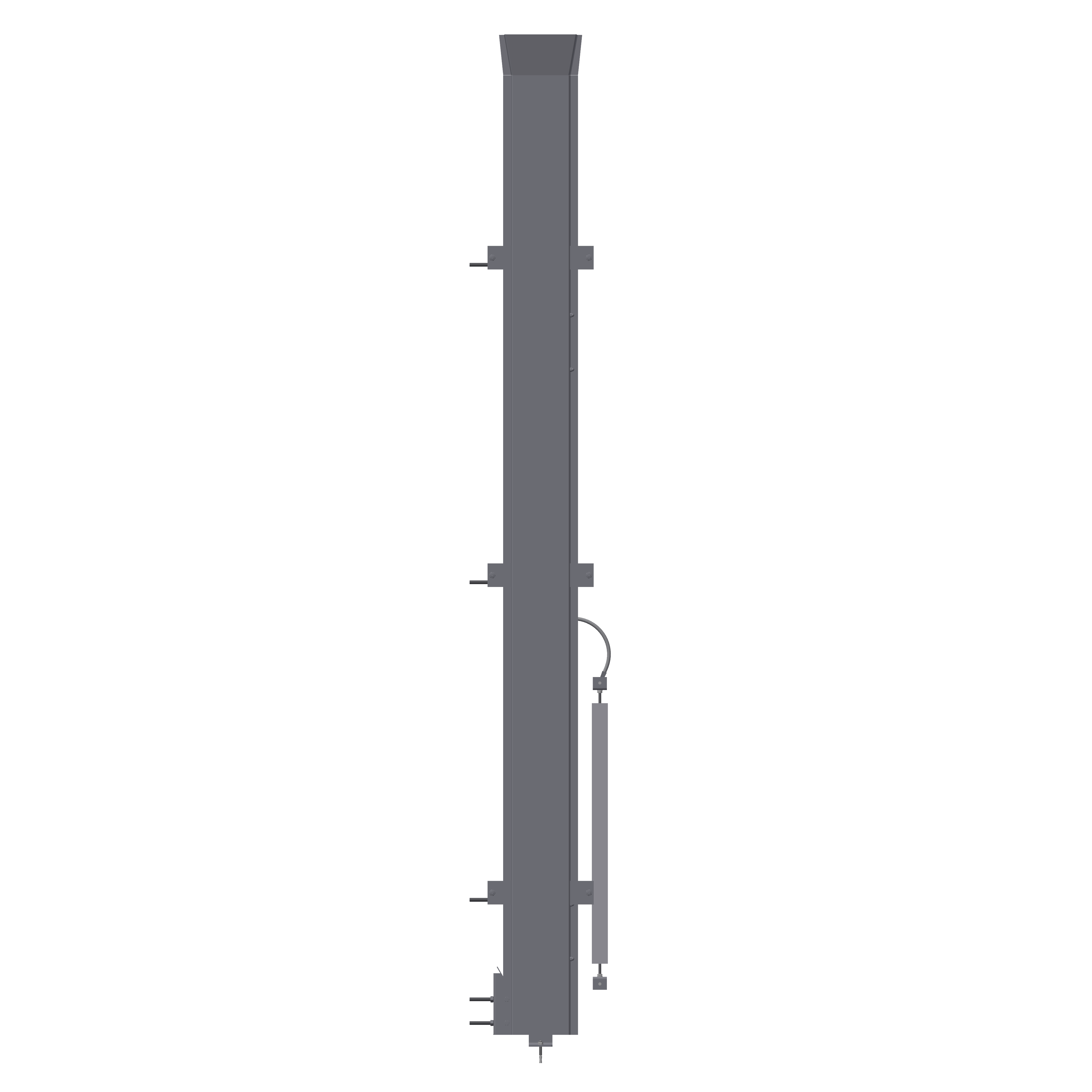

Stoplog

Hubert stoplogs are constructed to match the expected water pressure in individual situations. For deep water, the stoplogs are made in two or more sections. The seals are mounted on the flat side of the stop logs. Guides are installed in the side walls of the concrete channel to ensure optimum sealing and installation. A lifting beam & crane is used to place and remove a stoplog (segment). Hubert also supplies a storage frame. Naturally, cathodic protection is also possible.

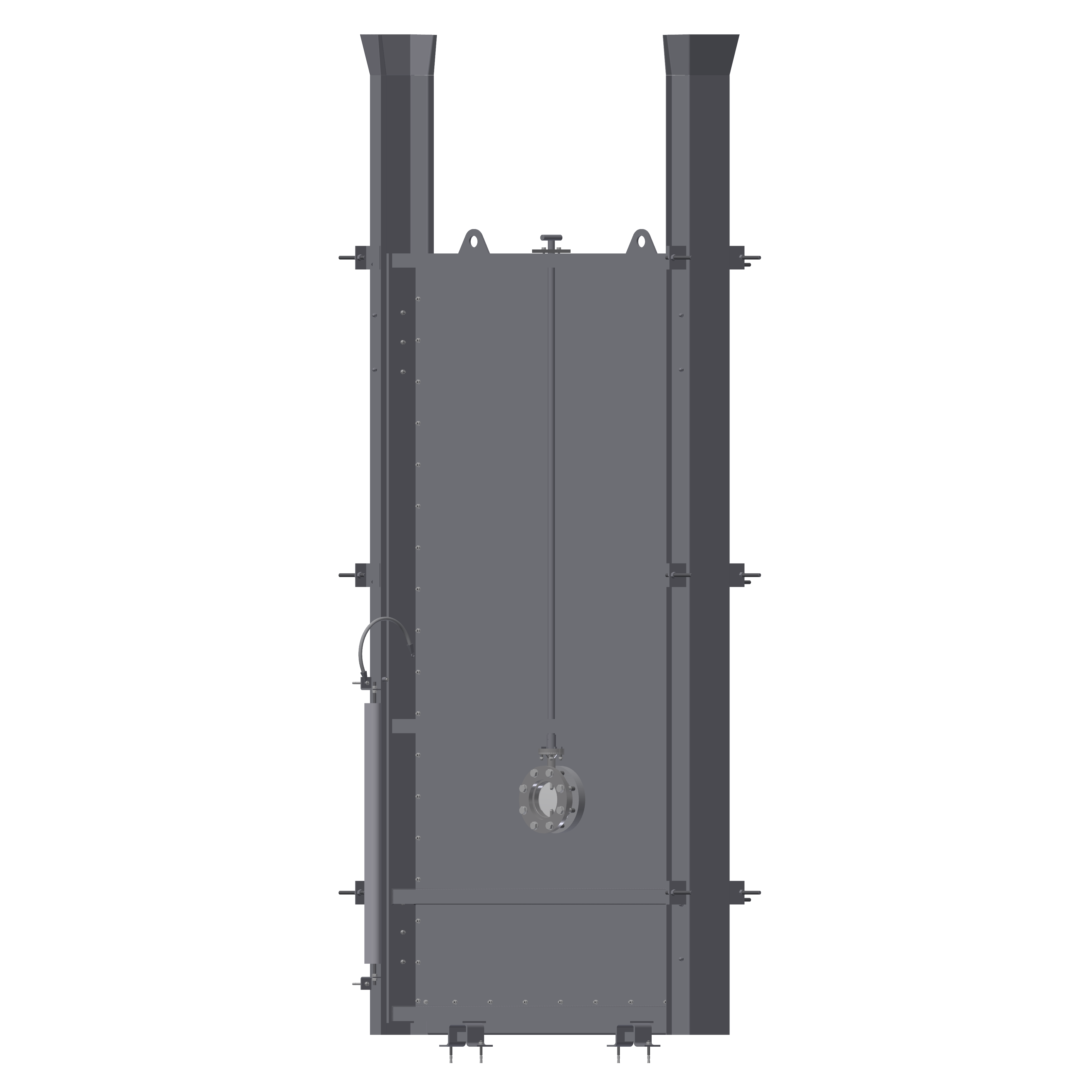

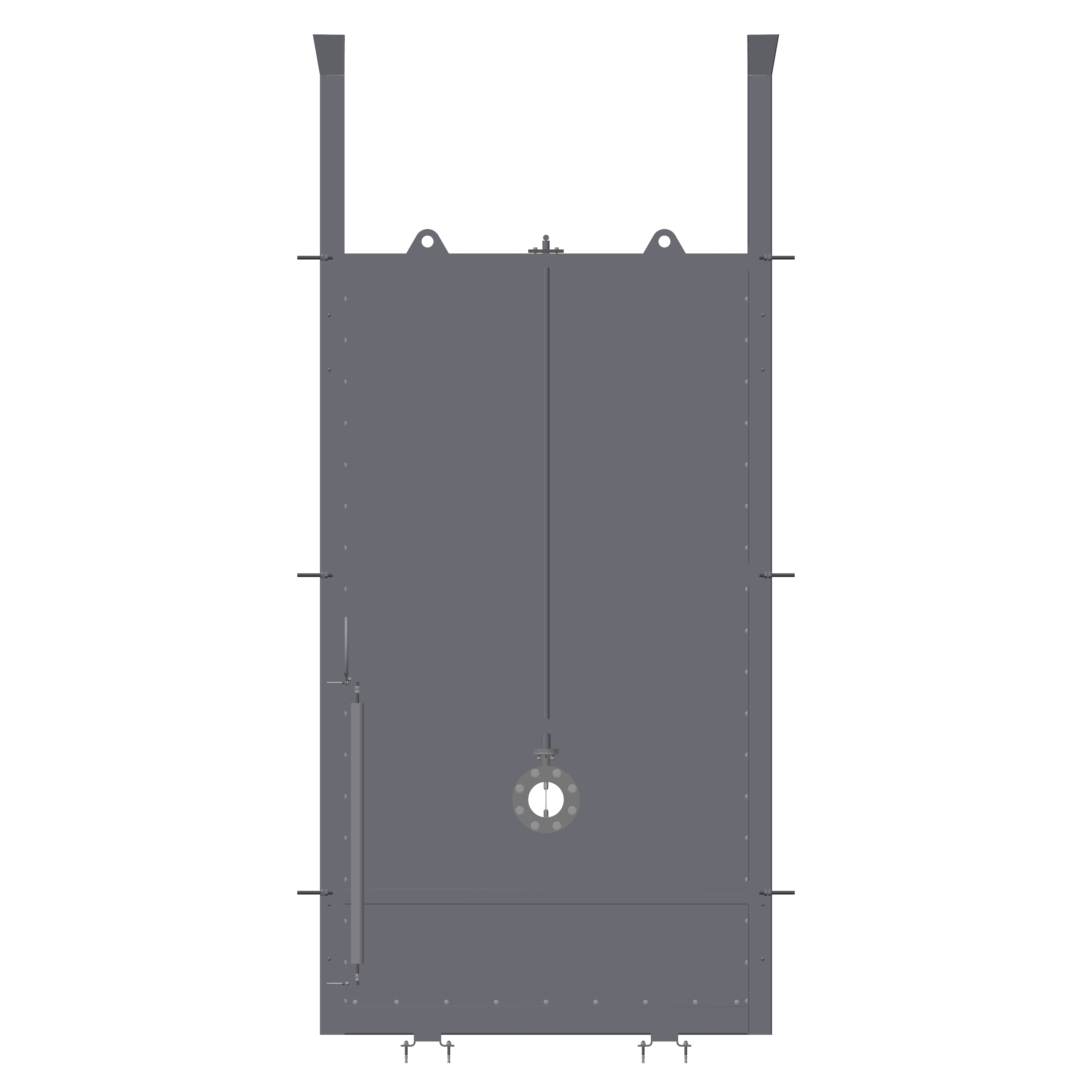

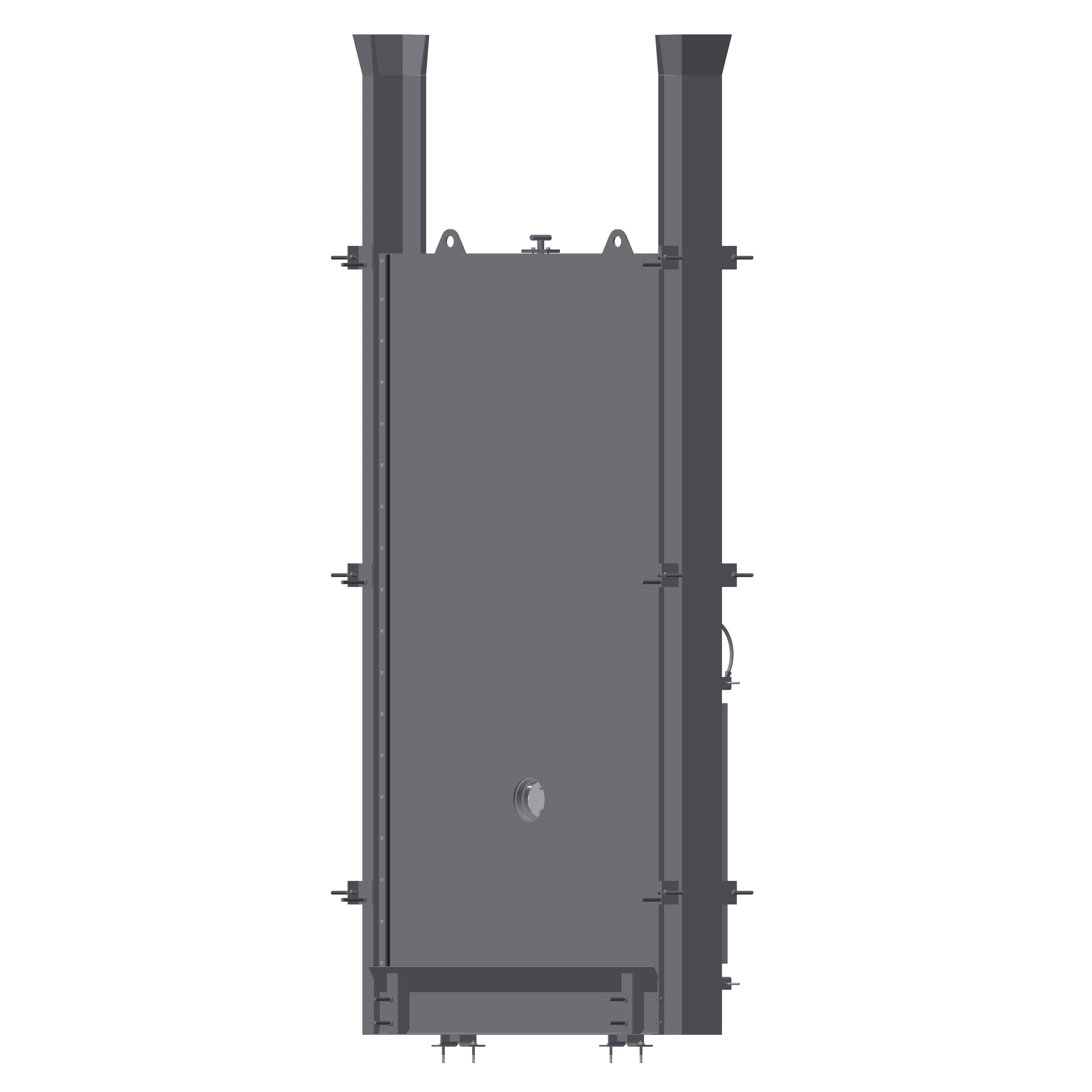

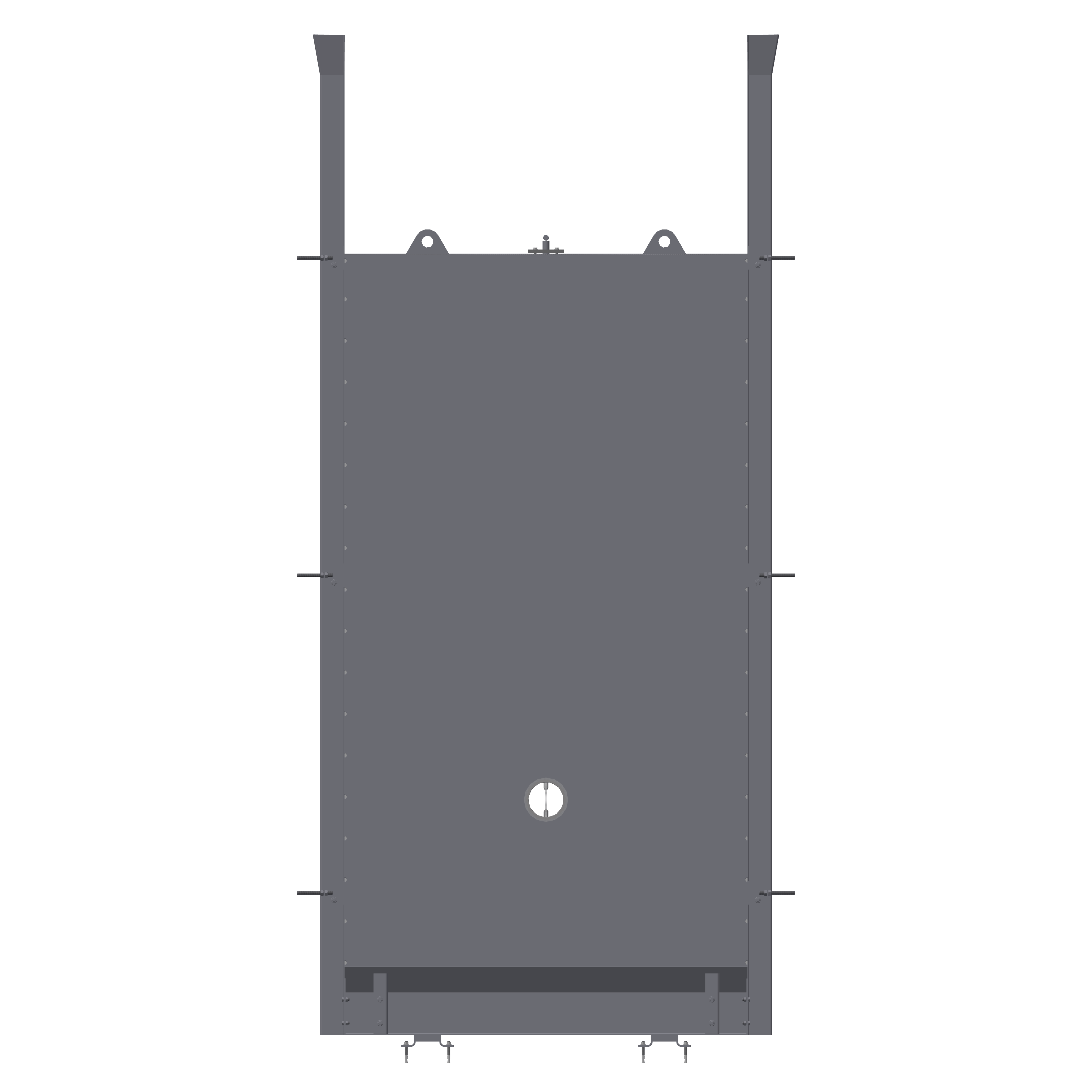

Sluice gate

Hubert sluice gates are often placed after a supply line and therefore guiding and sealing is done slightly differently than with stop logs. A sluice gate construction is installed in the side walls of the concrete channel to ensure optimum sealing and installation. A sluice gate is normally raised or lowered as one piece, whereby lifting and lowering can be motorized and possibly automated. This additional installation is located at the top.